Top 9 GUI Alternatives to Consider in 2024

GUI is a pivotal computer program enabling intuitive communication through symbols and visual metaphors. It revolutionized user interfaces, with roots in innovators like Vannevar Bush and Douglas Engelbart at Xerox PARC. GUI became a standard in PC interfaces and is crucial in human-computer interaction.

For those exploring alternatives to GUI, choices encompass HMI, SCADA, PLC, OIT, HCI, Tungsten, LED, DCS, MES, and more.

HMI

Unveil your eyes to the world of HMI (Human-Machine Interface), the magnificent canvas that bridges the gap between man and machines, orchestrating a symphony of exchange and interaction with industrial systems. It’s the dashboard of progress, allowing monitoring and control of processes, not limited to but often relying on the illustrative efficiency of GUI (Graphical User Interface).

HMI Top Features

- Data Display: HMIs render an intuitive platform for data visualization, integrating information from multiple sources.

- Production Tracking: They enable the tracking of production time, trends, and tags, safeguarding efficiency and guiding optimization.

- Monitor Inputs & Outputs: HMIs facilitate monitoring of machine I/O, offering a clear view of performance metrics in real-time.

- Interface with PLCs: Their crucial link with Programmable Logic Controllers allows them to harness and display potent data.

- Highly Adaptable: Modern HMIs extend their reach to edge-of-network environments, devices, and integrate augmented and virtual reality technologies for enhanced visualization.

| Role in SCADA Systems: | Aiding intelligent actions in SCADA (Supervisory Control and Data Acquisition) systems; amplifying situational awareness and making control systems centralized and swift. |

| Remote Monitoring: | Enabled with cloud communication, they facilitate remote access for monitoring and analysis. |

| Interactive touch-screens: | In a world of touch-gadgets, HMIs have evolved touchscreen interfaces allowing swift operation and convenience. |

HMI Limitations

- HMIs require a change in mindset among users for effective utilization. Employee training for new technologies might be necessary.

- Depending on the complexity, the implementation of HMI systems can be complicated and time-consuming.

- A robust network infrastructure is essential for effective remote monitoring, access, and cloud data transfer.

HMI Use Cases

Use case 1 – Industrial Plants

In industrial atmospheres, HMI reigns supreme, replacing traditional systems to elevating process dynamics from monitoring to controlling, navigating to resolving, and visualization to intelligent decision making.

Use case 2 – Energy and Power Sectors

Integrating seamless operations with strategic analytics, HMI tailors itself impeccably in the heart of the energy and power sectors, enhancing situational awareness and leading the charge for dynamic process control.

Use case 3 – Manufacturing

From assembly lines to quality control, HMIs prove crucial in the manufacturing industry, providing real-time data access, monitoring machine performance, and tracking production metrics, enriching the industrial narrative with digital prowess.

SCADA

SCADA, or Supervisory Control and Data Acquisition, is a centralized control system that automates and supervises complex industrial processes. Predominantly used in a myriad of industries like energy, oil and gas refining, water and waste control, and telecom, it detects, corrects problems and measures trends over time.

SCADA Top Features

- Diverse Component Suite: Comprising of RTUs, sensors, SCADA master units, control relays, and communication channels, SCADA presents a robust control and automation system.

- Flexible Input/Output Hardware: The SCADA system features varied I/O signal hardware, networks, and controllers. Its database and software components help process vast volumes of data.

- Effective Site Control: SCADA field devices like RTUs and PLCs handle site control, enabling secure and efficient monitoring.

- User-centric HMI: The Human Machine Interface serves as a master station that processes and communicates data to the human operator.

- Evolutionary and Modern: SCADA has evolved from monolithic systems to distributed and networked models. Modern SCADA leverages SQL databases and rapid application development.

| Future-Ready technology | Cybersecurity Concerns |

|---|---|

| Prospects of integrating with 5G networks and quantum computing, and applications of edge computing, artificial intelligence, and machine learning. | With increased integration and connection, SCADA systems pose cybersecurity risks that need to be addressed. |

SCADA Limitations

- Legacy Systems: Legacy SCADA systems lack features like scalability, interoperability and have limited options for support.

- PLCs Costs: While efficient, the use of Programmable Logic Controllers often results in long-term costs.

- Cybersecurity: Increased connectivity and integration bring about cybersecurity challenges.

SCADA Use Cases

Use case 1 – Industrial Plants

Industrial plants can harness SCADA for efficient control and monitoring of complex processes, thereby ensuring optimal resource utilization.

Use case 2 – Energy Sector

Energy sector can leverage SCADA for real-time data processing, log recordings, and local/remote control of industrial processes.

Use case 3 – Water and Waste Control

Water and waste management can benefit from SCADA’s monitoring and control capabilities for effective and efficient waste control.

PLC

The Programmable Logic Controller (PLC), an invention of the 1960s, has been a game-changer in the world of manufacturing automation. Constant evolution and computational advancements over the past decades have led to PLCs being not just smaller, faster, and more powerful but also a lynchpin in the internet big data and AI revolution on the factory floor.

PLC Best Features

- Flexible and adaptable, capable of being programmed in relay ladder logic or newer programming languages.

- Integrated with ERP, MES systems, and SCADA to enhance manufacturing operations’ efficiency and performance.

- Offers advanced capabilities like vision system integration, motion control, and support for multiple communication protocols.

- Employs ladder logic, a visual representation of Boolean Logic, making it easier to understand for engineers.

- Monitors and records run-time data like machine productivity and operating temperature., thereby useful in start-stop processes and generating alarms during machine malfunctions.

| Component | Function |

|---|---|

| CPU with processor | The brains of the PLC, processing the information and driving the output based on the programmed logic. |

| Input/Output Modules | Interfaces that connect the PLC to the outside world, capturing real-time input data and driving physical output processes. |

| Power Supply | Powers the entire PLC unit and ensures uninterrupted operation. |

PLC Limitations

- They can become complex, resulting in difficulty in troubleshooting.

- Require a skilled workforce for optimal usage.

PLC Use Cases

Use Case 1: Robotic Arm in Cars Manufacturing

PLCs are widely adopted in the automobile industry to control and automate robotic arms. The PLC’s motion control feature ensures precise movement, resulting in enhanced productivity and quality.

Use Case 2: Airport Runway Control

Regulating the lighting, meteorological devices, and other systems on an airport runway require high-level coordination, which is where PLCs play a vital role.

Use Case 3: Textile Equipment

In the textile industry, PLCs manage spinners, looms, and other equipment, optimizing production processes and reducing machine downtime.

OIT: A Peek into a New World of Control and Interface

Welcome to the world of OIT (Operator Interface Terminal). A plethora of features await you, with intuitive options for display, communication, and control. Your gateway to ease and effectiveness.

The Best of OIT

- Exceptional Read/Write Functionality with controller internal registers.

- Ability to monitor Message Request Register (MRR) that triggers display and action for specific function codes.

- Rich multiscreen support for dynamic interaction with the OIT.

- Multiple language support to make it universally applicable.

- Utilize Control Key Coils & Function Key Coils for robust OIT-Controller data transfer.

| Unique OIT Feature | Explanation |

|---|---|

| Linear Scaling on Registers | Transforms data into operator-readable format, ensuring easy understanding. |

| Status Register | Enables synchronized sharing of info, messages, alarms, errors etc., between OIT and controller. |

The Limitations of OIT

- Limited to monitoring only up to 16 set points in controller memory simultaneously.

- Additional costs for premium features like private cloud server and virtual machine management via Boulder OIT.

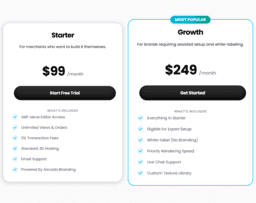

OIT Pricing

An idea of the pricing: Private cloud server at $115/month, Virtual Machine Management at $30/month, with 24×7 support at $20/month. Costs for extra features like VM CPU and VM Storage are charged separately.

OIT Use Cases

Use Case 1: Robust Control Systems for Industrial Equipment

OIT shines in managing intricate equipment like ovens, autoclaves, and clean-in-place systems. It allows real-time monitoring of parameters such as temperature, time, and pressure. Perfect for both batch and continuous manufacturing environments.

Use Case 2: Enhancing Readability and Functionality in Process Monitoring

The shift to flat-panel display has improved readability considerably with OIT. Glove-hand operations and personal computer interfaces have become more prominent, leading to decreased keypad operation & text-only displays.

Use Case 3: A Powerhouse for Industry-Wide Deployments

It is no coincidence that industries are increasingly turning to OIT. Thanks to its flexible features, OIT has found wide applications in discrete manufacturing, continuous processing, robotics, and warehousing.

HCI

In today’s technology landscape, the convergence of compute, storage, and virtualization has propelled a software-centric architecture rising to prominence: Hyper-converged Infrastructure (HCI). Tightly integrated to function on x86 hardware, HCI addresses the diverse challenges arising in heterogenous environments.

HCI Top Features

- Unified Management: HCI uses a unified management system to pool resources efficiently.

- Intelligent Multi-system Updates: With HCI, users have access controls for systematic updates via vCenter Administrator account.

- Encrypted Security: User credentials for cluster updates are securely preserved in an encrypted RSA lockbox within each VxRail Manager.

- License Evaluations: HCI System Software license is standard for VxRail nodes, with cluster updates enabled by CloudIQ via an add-on license.

| Feature | Description |

|---|---|

| Independent Scaling of Compute and Storage | NetApp HCI enables scalability of compute and storage independently, making it perfectly adaptable to different workloads with assured performance. |

| Integrated with vSphere UI | NetApp HCI integrates effortlessly with vSphere UI, presenting an easy-to-follow interface for storage clusters. |

| Support for Container Clusters | Companies using HCI can leverage its features for machine learning, deep learning algorithms, streaming data analytics, and crucially, for support in edge computing. |

HCI Disadvantages

- Power Density: High power density can pose potential challenges.

- Vendor Lock-in: With scalability comes possible vendor lock-ins.

HCI Use Cases

Use Case 1

Conducting real-time data analytics tasks becomes smoother with HCI’s integrated architecture allowing for efficient and active management.

Use Case 2

Businesses seeking rapid deployment speed, agility, and a more organized architecture can take advantage of HCI’s software-defined virtualization technologies.

Use Case 3

With its capability to independently scale compute and storage, HCI is particularly beneficial for data-heavy applications and enterprises seeking flexible, performance-tailored solutions.

Tungsten

Integrating the strength of the rare metal it is named after, Tungsten fabric offers a robust suite of services for your cloud and network functions virtualization (NFV) infrastructure.

Tungsten Top Features

- Orchestration platform compatibility: It includes plugins for platforms such as Kubernetes, OpenShift, Mesos, OpenStack, and VMware vSphere.

- Comprehensive management: Tungsten provides configuration, control, and analytics nodes.

- Scalability and Data Analysis: Maintains a scalable network model and state while collecting and analyzing network data.

- vRouter: This key component runs on compute nodes providing native Layer 3 services.

- Integrated Services: Provisions workflows via API and integrates with service provider OSS/BSS.

| Feature | Description |

|---|---|

| Technology Alliances | Collaborates with technology powerhouses like Red Hat, Mirantis, Canonical, and NEC. |

| Tungsten vRouter | Offers native Layer 3 services for the Linux host it runs on or for host’s containers/virtual machines. |

Tungsten Limitations

- Lack of futures contract trading, independent pricing references are used instead.

- Given its advanced capabilities, it may require a deep understanding of the system for efficient management.

Tungsten Use Cases

Use case 1

Large tech companies could utilize Tungsten to manage their vast cloud or NFV infrastructure landscapes. Its readiness to integrate with popular platforms allows strategic technology alliances, driving business growth.

Use case 2

Service providers can adopt Tungsten for its ability to integrate with OSS/BSS and provision workflows via API, enabling seamless service delivery.

Use case 3

The compound and alloy companies could harness the thermal properties and hardness of Tungsten for high-speed precision tool manufacturing, enhancing product durability and efficiency.

LED

Once regarded as the future of lighting, LEDs are now commonly integrated into various lighting systems including advanced smart lighting. Emerging from the revolutionary digital memory evolution in the 1970s and 1980s, LED technology continues to transform our visual experience.

LED Top Features

- Advanced integration: Practical for integrating advanced LED technologies.

- Interoperability: 0–10V signal standardized in 1970s for interoperability across different systems.

- DMX512 protocol: Still in use, enabling control over a ‘universe’ of data- 512 channels.

- Wireless control: Wireless technology enhances flexibility, adaptability, and reduces installation complexity.

| Feature | Benefit |

|---|---|

| Scalability | Wireless technology allows for scalability over time, easing the updating process of traditional solutions. |

| Installation | Wireless installations are up to 70{66f7997927a862c9f57ec7dffc6a2fe6d405caee7001dff533b976d48fe118b1} faster, cutting down on setup time. |

| Application-based setup | Wireless control enables simplified, real-time app-based setup. |

LED Limitations

- The requirement of a wire from console to each dimmer initially increased infrastructure complexity.

- LED fixtures and moving lights may require more than one DMX channel, thus increasing data needs.

- High feature additions, like voice control and smart bulbs, can drive the cost higher.

LED Pricing

Smart lighting systems’ cost varies extensively based on various factors. Basic setups can cost between $200 and $500 per room while advanced systems may range from $500 to $2000 per room. Whole-house systems could run you anywhere between $3000 and over $10,000.

LED Use Cases

Home Safety

LED smart lighting can provide home security benefits, contributing to a more secure living environment.

Energy Management

LED technology is known for energy efficiency, allowing for considerable energy management and conservation.

Mood Lighting

Flexible LED systems facilitate custom mood settings, enhancing the ambiance of your living space.

DCS

Meet DCS, or Distributed Control System, an automated Cinderella of control systems. It distributes its functions across countless elements, revolutionizing industries that perceive nuances of innovation. It operates on a core notion of decentralized control principle and backs it up with data. As per the forecast, DCS revenue is strutting towards a smash-hit $23.37 billion mark by 2025 with a CAGR of 4.5{66f7997927a862c9f57ec7dffc6a2fe6d405caee7001dff533b976d48fe118b1}.

DCS Top Features

- Single Processor Failure Mitigation: Whenever a processor bids adieu, DCS structure takes the charge to recover without inducing side effects.

- Operator Supervisory Control: The centralized control system enhances reliability, ultimately slashing the installation costs.

- Varied Applications: DCS doesn’t shy away from showing its prowess in sectors ranging from power generation to pharmaceuticals, and from manufacturing to biotech.

| Feature | Description |

|---|---|

| Integration Ability | DCS is a team player. It cooperates, integrates, and plays well with existing industry architectures. |

| Database Management | The system’s configuration tools are meticulously designed for flawless database management, system security, and graphical presentation. |

DCS Disadvantages

- Despite its glittering features, DCS may be outshine by PLC when it comes to real-time actions.

- The advanced process control of DCS might fall short in front of larger facilities and substantial I/O points.

DCS Use Cases

Use case 1

Power Generation: Electricity utilities can ride the wave of DCS to control the varying processes for efficient power generation.

Use case 2

Oil and Gas Industry: Wish to streamline the diverse processes in petroleum refineries? DCS maintains the rhythm satisfyingly well.

Use case 3

Biotech and Pharmaceuticals: The precision is key here and DCS provides exactly that, ensuring pharmaceutical recipes are followed to the T.

MES

Improving the control and efficiency of manufacturing operations, MES (Manufacturing Execution Systems) are expertly designed for real-time tracking and documentation in the process of material transformation from raw to finished products.

Top MES Features

- Resource Scheduling: Intelligent management of personnel, machines and support services.

- Order Execution and Dispatch: Seamless control of product lifecycle management.

- Production Analysis: Provides insights into downtime management and product quality.

- Materials Tracking: Real-time tracking of resources, machines and human effort.

| Integrated Automation | Regulatory Compliance |

|---|---|

| Automated workflows, equipment assignment, alerts for production bottleneck detection. | Offers “as-built” records essential for regulated industries. |

MES Downsides

- Cost of implementation is relatively high ranging from $375,000 to $1.2 million.

- Requires smooth integration with existing IT systems for optimal performance.

MES Pricing

The cost of implementing MES ranges between $375,000 and $1.2 million, depending on the scale and complexity of the manufacturing processes.

MES Use Cases

Use case 1: Industrial Automation

Incorporates automated workflows and employee scheduling for faster and efficient processes, making MES indispensable for industries leveraging industrial automation.

Use case 2: Regulatory Compliance

MES excels in industries seeking regulatory compliance such as pharmaceuticals. The “as-built” record keeping and product tracking promote transparency and adherence to standards.

Use case 3: Optimized Resource Allocation

With the ability to provide real-time tracking of resources and materials, MES proves invaluable for companies aimed at minimizing waste and streamlining their inventory management.