First Step in Choosing: HMI vs LED

When comparing HMI vs LED, HMI’s versatile usage in multiple industries makes it a necessary tool for operators, system integrators, and control system engineers, especially for digitizing and centralizing data. LED, particularly within wireless systems, is ideal for its seamless adaptability and lighting control. Opt for HMI for industrial processes. Choose LED for smart, energy-effective lighting controls.

Key Differences Between HMI and LED

- HMI interfaces with Programmable Logic Controllers (PLCs) and input/output sensors, vital for data acquisition and real-time monitoring of operations like temperature control and equipment functionality. LED systems do not have this feature.

- LED systems, especially within smart lighting, can be controlled wirelessly, allowing for superior design flexibility, easy integration, and reduced logistical constraints. HMIs do not generally include built-in wireless operational capabilities.

- HMIs play a key role in industrial processes ranging from energy to transportation whereas LED systems find more relevance within aesthetic setups and lighting control.

- The future of HMI technology is leaning towards AR and VR for detailed visualization, while LED technology is heading towards maximizing smart, energy-conservative lighting designs.

| Comparison | HMI Technology | Lighting Control Technology |

|---|---|---|

| Application Industries | Various industries including energy, food and beverage, manufacturing, oil, gas, power, recycling, transportation, water/wastewater. | Primarily used in buildings and facilities for energy management, home security. |

| Controller at Core | Programmable Logic Controllers (PLCs). | Dimming panels or smart controllers. |

| Signal/Protocol | Can interface with various protocols depending on PLC and sensors. | Standardized on 0-10V signal. Extended to DMX512 in modern systems. |

| Evolution of Technology | Moved from simple monitoring to complex control using touch-screen HMIs and mobile devices. AR/VR for manufacturing visualization. | First using sliders for control to computerized controllers, punch card memory systems, digital memory, and now wireless smart systems. |

| Benefits | Improves industrial processes; Provides data acquisition, situational awareness, faster development, less time spent navigating. | Wireless lighting system reduces installation time by 70{66f7997927a862c9f57ec7dffc6a2fe6d405caee7001dff533b976d48fe118b1}, provides design flexibility, efficient energy use, enhances security, mood settings. |

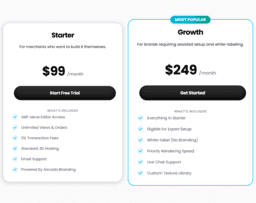

| Cost | Varies depending on implementation complexity, machinery involved, and other factors. | Basic smart systems: $200-$500/room, advanced systems: $500-$2,000/room, whole-house systems: $3,000 – $10,000+. |

| Recent Innovations | Use of AR/VR for data visualization, mobile HMI for remote monitoring, data moved to the cloud for remote access. | Wireless lighting control systems, integration with advanced LED technology, voice control, real-time app-based setup. |

What Is HMI/SCADA and Who’s It For?

A cornerstone of industrial operations, HMI/SCADA interfaces enable enhanced control over complex systems. Through these interfaces, operators can monitor, visualize, and optimize all aspects of operations. Overshadowing traditional plant systems, this technology is a critical tool for industries ranging from energy to water treatment. It’s tailored for engineers, system integrators, operators, and particularly control system engineers, who benefit from data centralization and digitizing industrial processes.

Pros of HMI/SCADA

- Boosts operational efficiency through data centralization

- Fosters continuous improvement culture

- Minimizes navigation time

- Aids in rapid identification of critical data

Cons of HMI/SCADA

- Requires change in workforce mindset

- Implementation can be cost-intensive

- Complexity in integration with existing industrial processes

What Is Advanced Lighting Control and Who’s It For?

Advanced Lighting Control revolutionizes illumination, offering optimal control over brightness, color, and energy consumption. The technology is not just about lighting; it’s about transforming space and mood dynamically. It’s perfect for homeowners and businesses desiring energy efficiency, enhanced security, and customizable ambience. Its cost-effectiveness and adaptability make it suitable across small dwellings to expansive facilities.

Pros of Advanced Lighting Control

- Fosters energy conservation

- Improves security measures

- Offers design flexibility

- App-enabled for real-time control

Cons of Advanced Lighting Control

- Installation cost can be high

- Complex systems require professional installation

- Dependence on wireless connectivity

The Final Verdict: HMI vs LED

Analysis made, let’s assess our two contenders, HMI and LED, for suitable audience segments.

The Industrial Operator

In the heartland of the industrial sector, HMI reigns. From its vast application within energy, manufacturing, and recycling industries, its centralizing and digitizing of data proves invaluable. For tasks such as monitoring pump statuses and water tank temperatures, the higher performance, touch screen HMIs provide the much-required instant monitoring and remote accessibility for the operator.

The Modern Engineer

The modern engineer would be best suited with HMI. As systems grow more complex, developments in AR/VR, alongside the evolution towards high-performance HMIs, equip engineers with more sophisticated tools to optimize operations. The trend towards data capturing and sending to the cloud for analysis propels the modern engineer towards a data-driven future.

The Budget-Conscious Homeowner

If you’re seeking to smarten your home with advanced lighting, but are budget-conscious, LED smart systems are a great fit. Basic systems can range from $200-$500 a room, catering to an audience seeking efficient solutions without breaking the bank, with added benefits like energy management and increased security.

The Modern Architect

Architects with a penchant for merging design aesthetics with advanced technological features gravitate towards LED. With wireless LED lighting systems, architects gain convenience and design flexibility while achieving faster installation times and enhanced future adaptability.

The choice between HMI and LED is beyond a binary inference. Rooted in your distinctive need, HMI stands unrivaled for industrial and complex system applications. Yet, if a streamlined installation, cost efficiency, and design flexibility are your priorities, LED lighting systems prove to be the superior choice.